Computerization of Industry

We Specialize in Real Time Exporting your Data to you Server.

NDT Visual Scanning

- Affordable Cost

- Applicable in various industries, Industrial to Medical

- Alternative of X-Ray Vision

- Detect Internal Defect

- Non Destructive TeraHertz Vision

Custom Measuring Scope Data Transfer System

- Affordable Cost

- Instant Transfer of Measuring Data to server

- Applicable to SECS/GEM, SQL, SPC and etc

- Tailored Interface with operator usage in mind

- Custom coded for various company requirements

- Nikon / Olympus / Hisomet / STM6 / SMT7 / MN200 / MN400 / MN800

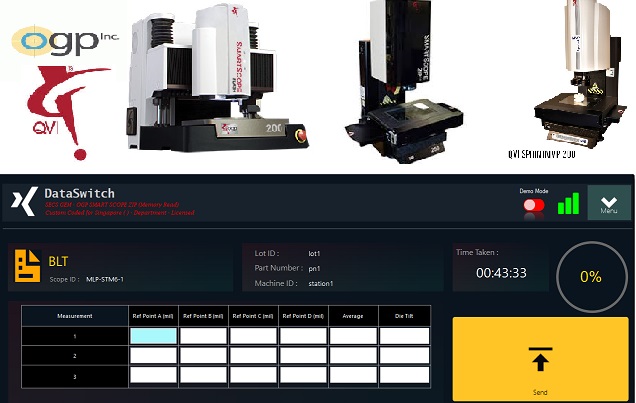

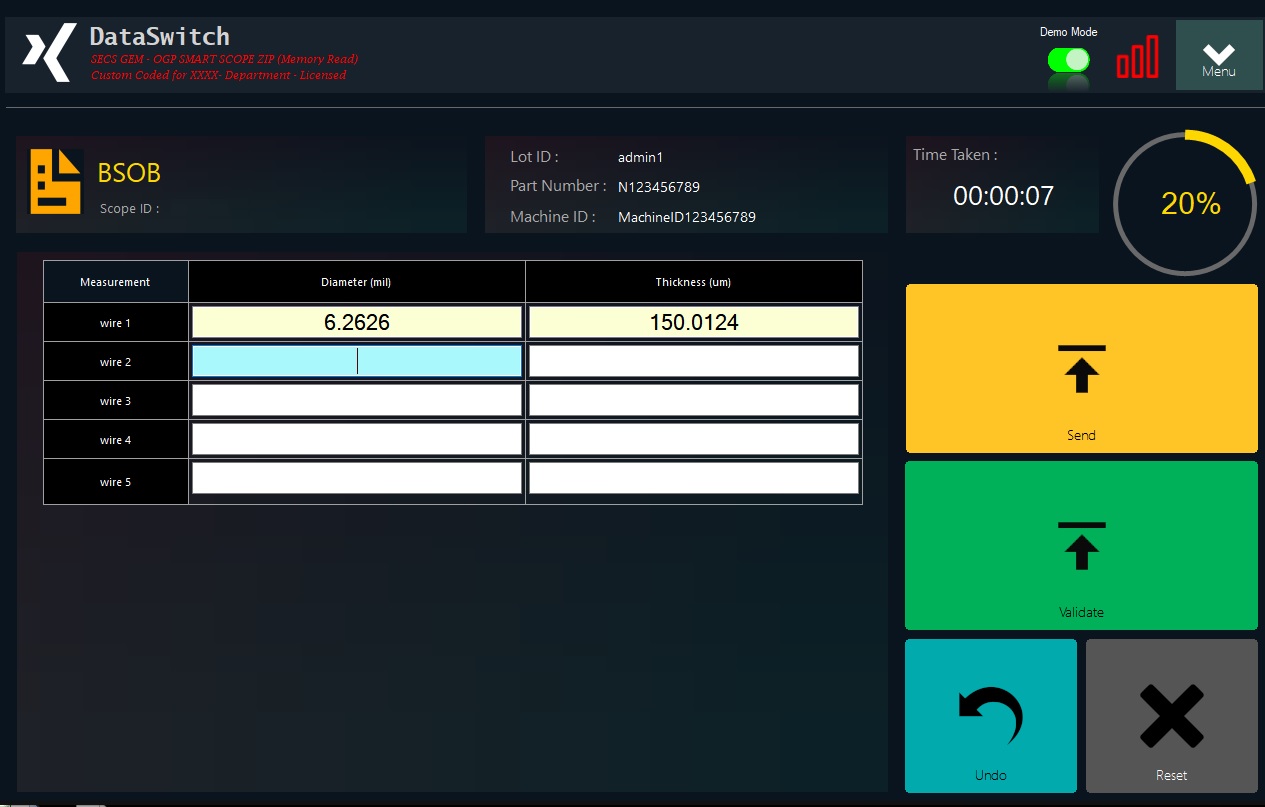

Custom Smartscope Data Transfer System

- Affordable Cost

- Real Time Transfer of Measuring Data to server

- Applicable to SECS/GEM, SQL, SPC and etc

- Reaing Data Directly from Manufacturer Program

- Custom coded for various company requirements

- OGP / QVI / SMARTSCOPE FLASH / SMARTSCOPE ZIP

Custom SECS/GEM Interfacing Software

- Affordable Cost

- 2 way communication interfacing

- 3 built in Input Method

- Simple Interfacing and setup

- Interfacing SECS/GEM or SQL to your machine

Effortlessly transfer all your metrology data to your server in real time with DATASWITCH. Experience significant reductions in operator working hours and eliminate errors, both intentional and unintentional. Benefit from streamlined data collection, ensuring unparalleled speed and ease of use with Dataswitch.

- Computerized and provide secure data transfer within equipment and host

- Improving legacy equipment with inteligence features

- Fully customized according to user request/requirement

- Multiple lingual

- Customizable,cater for existing equipment/server

- Minimal equipment expenditure requirements

- Individual Product License

- Bulk Purchase License

- Coorporate License

- Onsite Debug/Troubleshooting

- Remote Desktop Supports

- 48 hours Response (With Contracts)

- Online Status Monitoring

- Carfted Notification Messages

Every successful solution begins with a problem or requirement. At the core of our system development process lies a deep understanding of user requests and requirements. We recognize that comprehending and addressing user needs is the fundamental starting point in building robust and effective systems.

The system design process entails comprehensive mapping of the entire system, ensuring a seamless flow from start to end while incorporating loops and stopping mechanisms. While this is a standard practice, the true essence lies in addressing abnormalities and ensuring system robustness. Manufacturing industries prioritize minimizing downtime, making the handling of anomalies and ensuring system resilience of utmost importance.

The technical implementation of the system involves various critical steps, including module development, integration, connectivity, rigorous testing, debugging, mapping of functionalities, variable definition, bug fixes, runtime monitoring, API integration, and memory allocation. These meticulous processes are essential to ensure a high-quality and robust system that meets the desired specifications and performance standards.

During the commissioning phase, the overall system performance is thoroughly tested to validate its functionality and reliability.

This includes conducting rigorous testing through various scenarios and error-proofing measures to ensure its resilience and robustness. Comprehensive testing, including inducing potential system failures like BSOD (Blue Screen of Death), is carried out to verify that the system remains stable and performs as intended even under challenging conditions.

sales@apacal.com +60 (10) 3950881

Kuala Lumpur

Malaysia

55100 KL